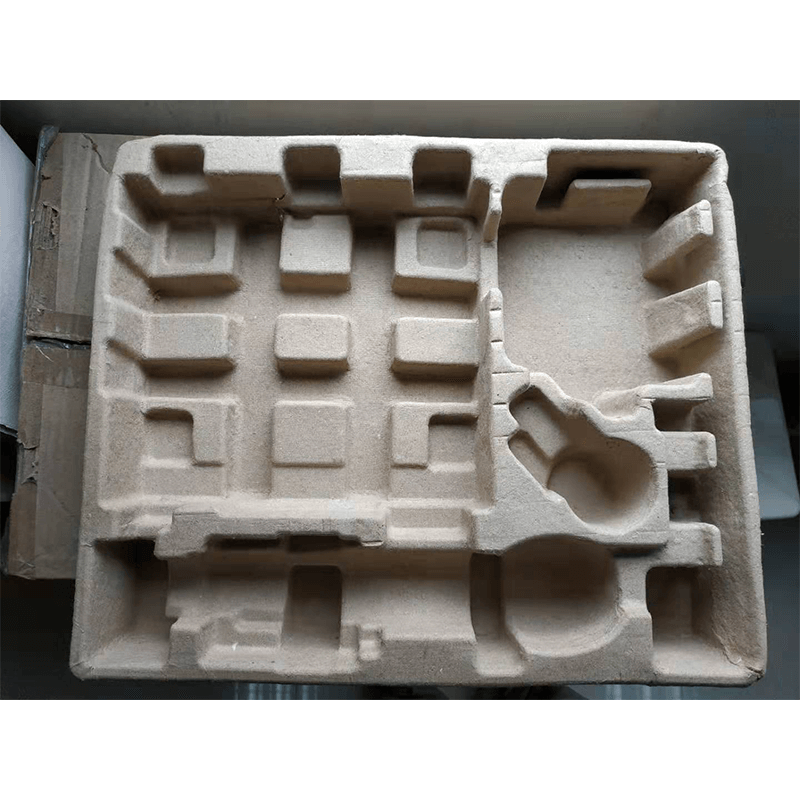

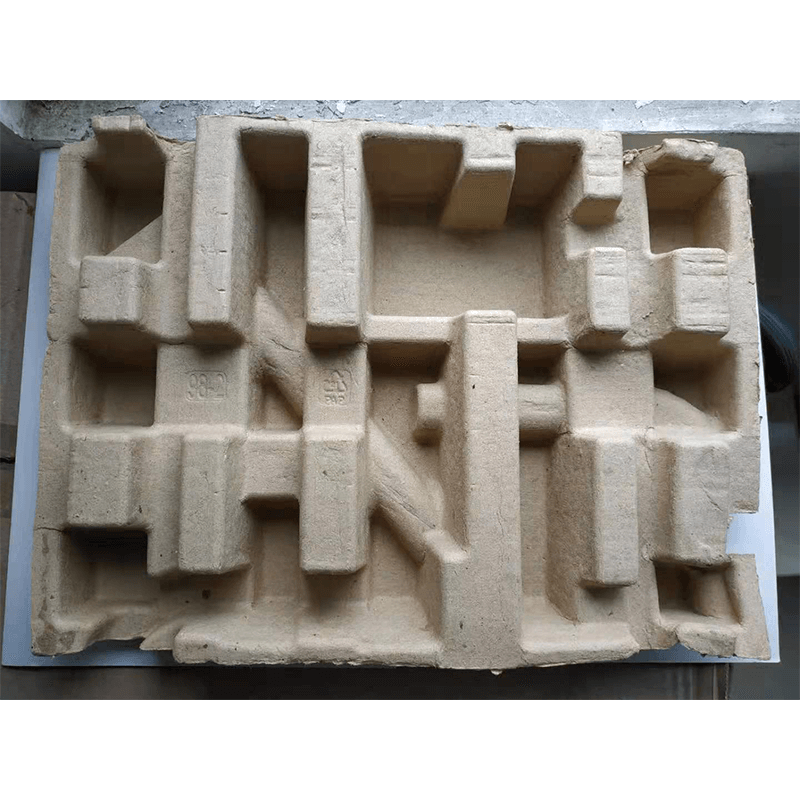

Packing method: export standard packing.

PULP MOLDING, commonly known as paper tray, pulp tray) is an environmentally friendly and economical packaging material.

The raw material of the paper tray is pulp fiber, which is 100% environmentally friendly. The tests such as ROHS/SGS/REACH meet the standards, which is conducive to the export of products, and also meets everyone's higher and higher requirements for product safety and environmental protection.

It uses various pulps as raw materials, which are pulped and formulated into a certain concentration of pulp, vacuum-adsorbed and formed on special molds and special equipment, and then dried to form lining packaging products of different types and uses.

Dry-pressed paper tray (pulp molding) has a geometric shape that matches the appearance of the package and good shock-proof, shock-proof, anti-static, anti-corrosion and other ideal protection effects, and its performance and efficacy have been tested by various physical indicators. It is enough to replace and superior to packaging products such as EPS, PS and PVC. A variety of auxiliary additives such as strengthening agent, flexibility agent, water repellent, oil repellant, and flame retardant can be added according to the requirements of different packaged products to achieve various functions. Physical properties can't do it. And it has an advantage in indicators and functions such as shock resistance, environmental protection, price and anti-static.