Industrial Packaging Production Equipment - Blow Molding Machine

Blow molding, also known as blow molding, is a manufacturing process that forms hollow plastic parts. The blow molding process is a molding method that uses gas pressure to inflate a thermoplastic closed in a mold into a hollow product, which is used to manufacture hollow products.

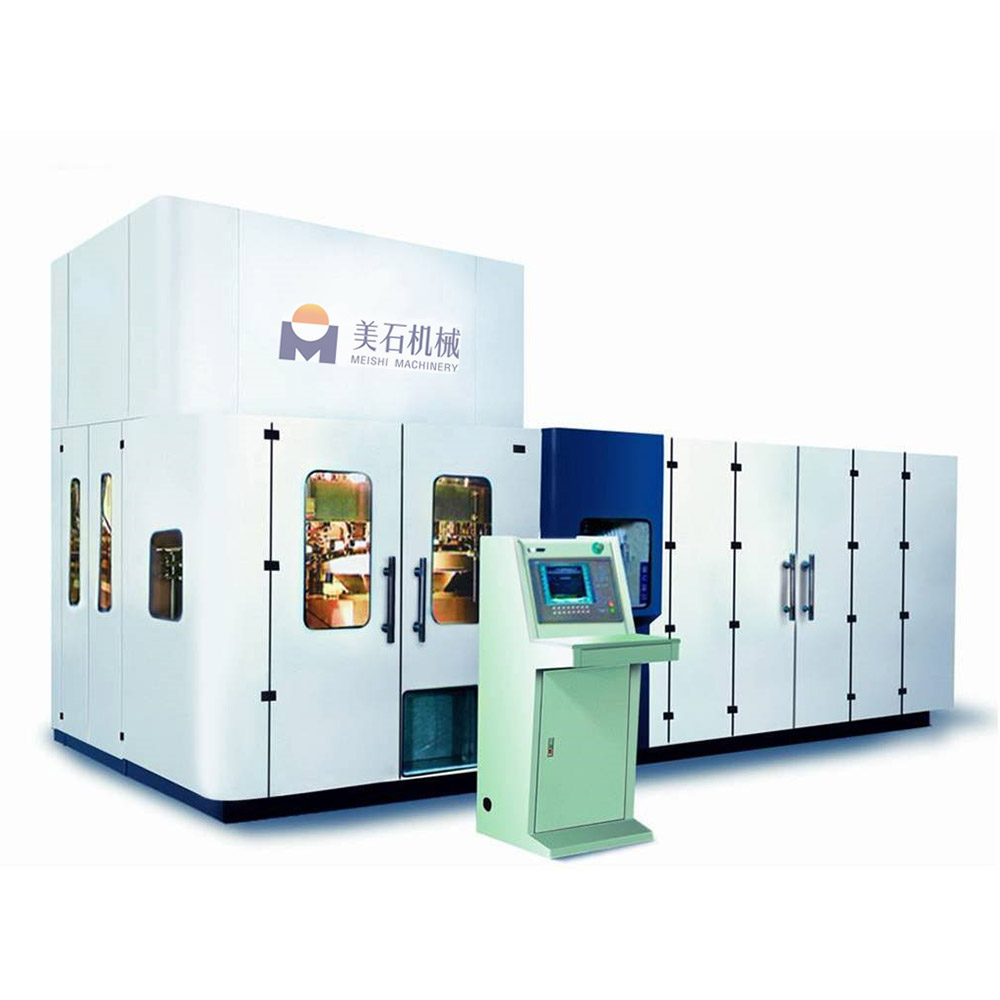

MEISHI adopts advanced bottle-making technology, using high-pressure compressed gas to blow PET preforms into high-speed rotary blow molding machines. The blow molding machine is used to produce various PET bottles. It has a high degree of automation and intelligence and has the characteristics of high output, low energy consumption, and no intermediate pollution. It reduces production costs for your production line and provides good visibility and maintainability, and security.