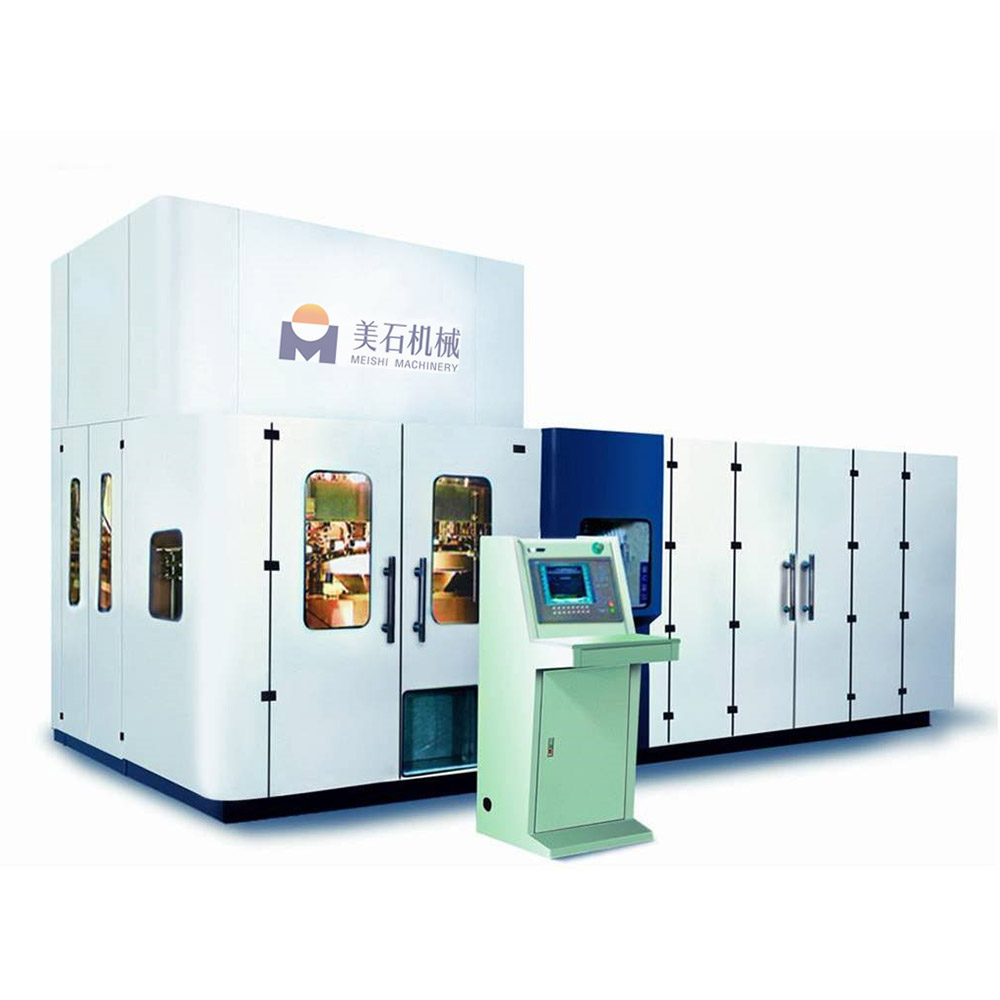

We are experienced Packaging Machine Supplier. Our Smart Packaging Technology allows us to have the ability to produce high-quality Smart Packaging Systems. Find the best container vacuum forming machine price here.

We are the experts for complex products.

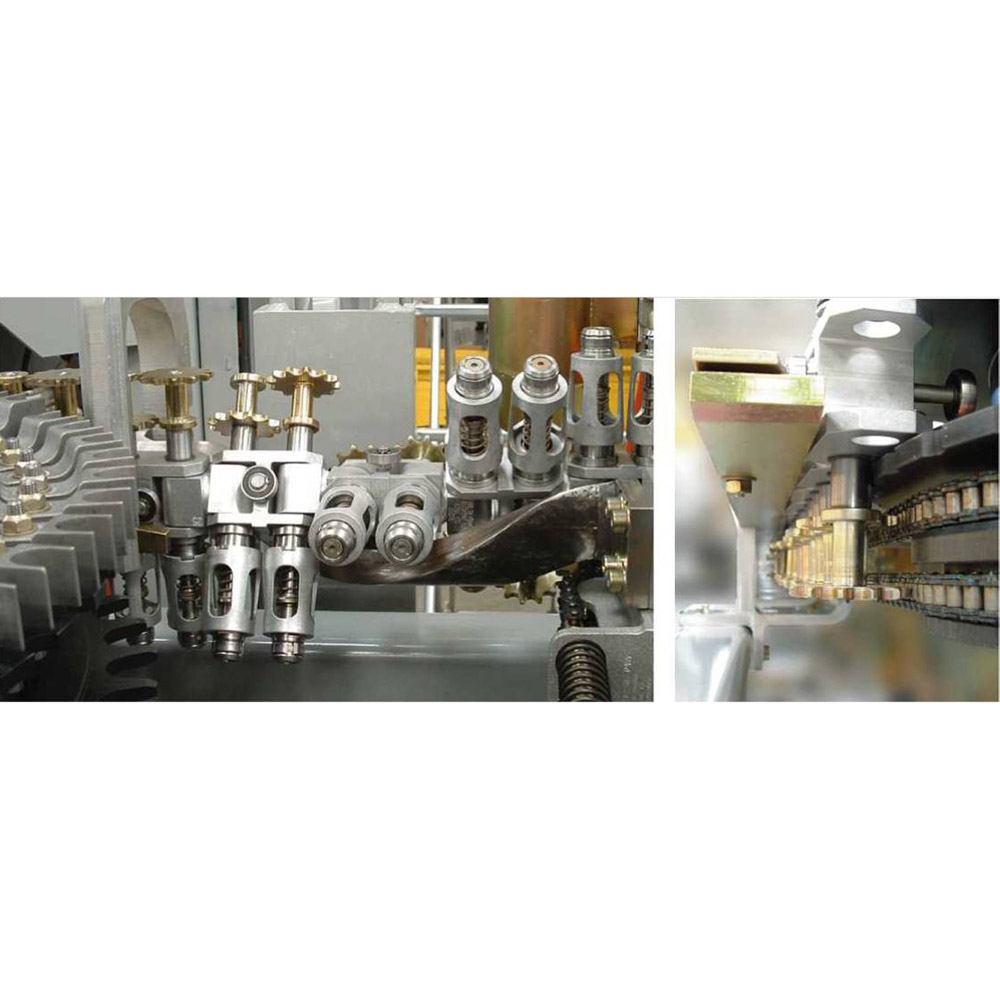

The high degree of automation and intelligence

Excellent and stable product quality

High output: single mold output 2000 bottles/hour

Low energy consumption: reduce air consumption and power consumption

High sanitation, no intermediate pollution

Lower production cost

Good visibility, maintainability, and safety

The latest model, 4 stations injetion stretch blow molding machine.