Automatic Tableware Production Line - Automatic Pulp Molded Machine

China pulp molding production line converts waste paper into pulp molded products without contamination. Automatic tableware production line easily complies with environmental protection requirements and green packing development.

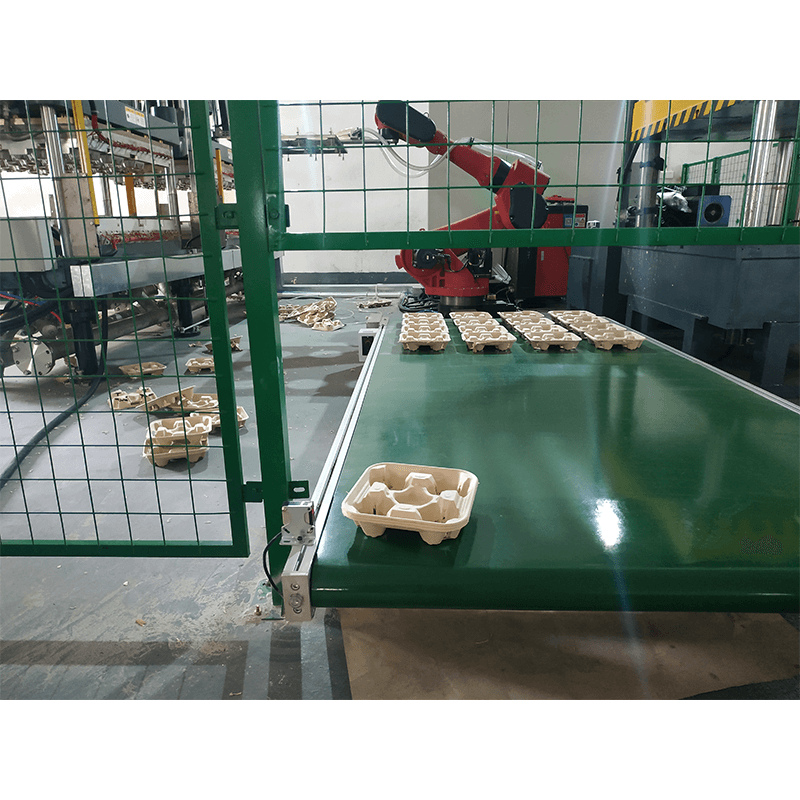

The pulp molded tableware production line is used to produce disposable pulp molded tableware. Pulp molded tableware products are produced by drying, hot pressing, trimming, and stacking processes.

The pulp molded production line supports real-time bus control of the servo drive, which acts as closed-loop control. In terms of its products, this production line belongs to the packing machinery industry. The end products of the china pulp molding production line have a wide application in protecting eggs, fruits, seedlings, etc.

As an automatic pulp molded equipment manufacturer and supplier, Meishi offers you a fully automatic pulp molded machine, and a fully automatic pulp molding production line. The automatic tableware production line is completed automatically and continuously without manual transfer, which greatly saves space, labor, and power consumption, increases the start-up rate, product qualification rate, and product quality, and is easy to maintain.

.jpg)