An automatic tableware production line is a manufacturing system that is designed to produce large quantities of tableware with minimal human intervention.

By automating the manufacturing process, companies can increase efficiency, reduce costs, and improve product quality.

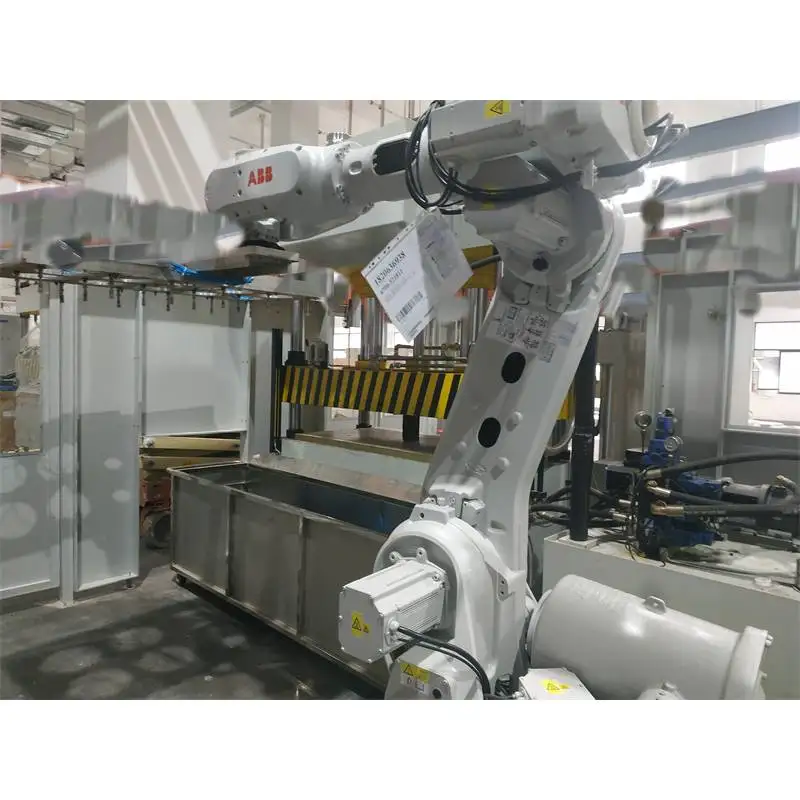

Automatic Tableware Production Line

An automatic tableware production line is a specialized manufacturing system designed for the mass production of tableware products. The production line typically includes automated machinery and equipment that can handle raw materials, mold them into the desired shapes, apply glaze or other coatings, and package the finished products.

The production line is typically designed to minimize human intervention and maximize efficiency. Raw materials are typically transported to the production line via a conveyor belt, where they are mixed with water to create a slurry. The slurry is then poured into molds to create the desired shapes and sizes of tableware.

Once the tableware is molded, it is transported to a drying station where it is allowed to dry and harden. The dried tableware is then glazed or coated with other materials to protect the surface and improve its appearance. Finally, the finished tableware is packaged and prepared for shipping.

Automatic tableware production lines and semi-automatic tableware production lines can be used to create a wide range of tableware products, including plates, bowls, cups, and cutlery.

Is an Automatic Tableware Production Line Worth Investing In?

One of the key advantages of an automatic tableware production line is that it can produce large quantities of tableware quickly and efficiently. By automating the manufacturing process, tableware manufacturers can minimize the need for human labor, which can help to reduce costs and improve production speed. Additionally, by using a standardized process, the quality of the finished tableware can be more consistent and reliable.

Another advantage of an automatic tableware production line is that it can be highly customizable. By adjusting the settings and parameters of the production line, companies can create tableware products that are tailored to their specific needs and requirements. This level of flexibility can be especially important for companies that need to produce specialized or custom tableware products.

In conclusion, an automatic tableware production line is a highly specialized manufacturing system that can produce large quantities of tableware quickly and efficiently. By automating the manufacturing process, companies can reduce costs, improve production speed, and increase product quality.

Many tableware manufacturers find that an automatic tableware production line is a worthwhile investment that can provide long-term benefits. Whether you are a small startup or a large established company, an automatic tableware production line can help you take your manufacturing capabilities to the next level.