Sustainability in manufacturing encompasses the reduction of waste, energy consumption, and environmental impact while optimizing resources. Traditional packing methods often contribute to excessive waste generation and inefficiencies, prompting a shift toward more sustainable alternatives.

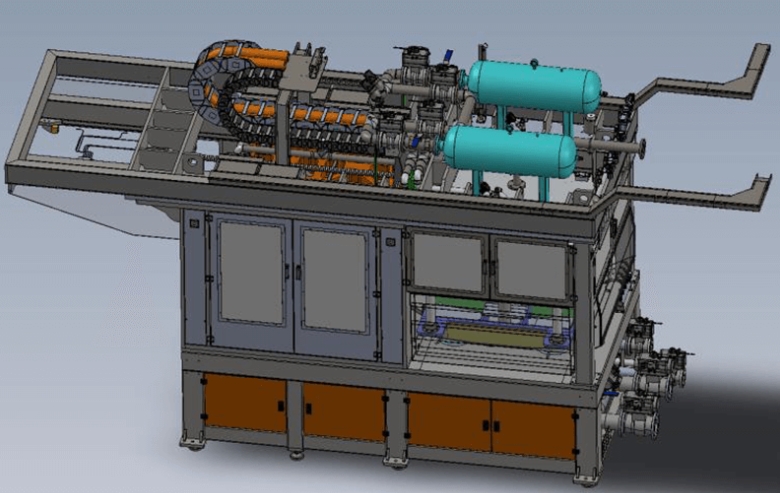

Role of Automatic Industrial Packing Production Machine

Automatic industrial packing production machines change the packing process by employing advanced technology for precision and efficiency. These machines facilitate streamlined operations, minimizing errors, and reducing material waste through precise measurements and packaging.

Eco-Friendly Features of Automatic Industrial Packing Production Machine

Use of Recyclable Materials: Many automated packing machines are designed to utilize recyclable packaging materials, reducing the environmental footprint of packaging.

Energy Efficiency: Advanced technology integrated into these machines optimizes energy usage, decreasing overall energy consumption during the packing process.

Reducing Material Waste

Accurate Measurements: Automated machines ensure precise measurements, significantly reducing excess material usage and minimizing waste.

Customization and Flexibility: These machines offer customization options, allowing manufacturers to tailor packaging sizes, minimize unused space and material.

Impact on Supply Chain Sustainability

Efficient Transportation: Optimized packaging through automated machines leads to reduced space requirements during transportation, cutting down fuel consumption and emissions.

Improved Inventory Management: Accurate packaging minimizes excess inventory, enhancing supply chain efficiency and reducing waste.

Integration Challenges and Solutions

Initial Costs: Implementing automated packing machines may involve significant upfront costs. However, the long-term benefits outweigh these initial investments, leading to cost savings over time.

Training and Adaptation: Proper training programs are essential to ensure the seamless integration of these machines into existing manufacturing processes.

Here are some frequently asked questions (FAQs) along with their responses regarding sustainability in manufacturing and the use of automated packing machines:

How do automated packing machines contribute to sustainability in manufacturing?

Automated packing machines contribute to sustainability by reducing material waste through precise measurements, optimizing packaging sizes to minimize unused space, and employing recyclable materials. They also enhance energy efficiency, leading to reduced energy consumption during the packing process.

Are automated packing machines cost-effective in the long run?

Despite initial upfront costs for implementation, automated packing machines prove to be cost-effective in the long run. They result in reduced material waste, lower energy consumption, decreased labor costs, and optimized supply chain efficiency, leading to substantial cost savings over time.

Do automated packing machines offer customization options for various products?

Yes, most automated packing machines offer customization options to accommodate various product sizes and shapes. They can be adjusted to meet specific packaging requirements, minimizing excess material usage and ensuring efficient use of packaging materials.

How do these machines affect the quality of packaging and product protection?

Automated packing machines are designed to maintain high-quality packaging standards and ensure product protection. They provide precise measurements and consistent packaging, reducing the risk of damage during transportation and storage.

Can automated packing machines be integrated into existing manufacturing setups?

Yes, automated packing machines can be integrated into existing manufacturing setups with proper planning and customization. They are versatile and adaptable to different production environments, allowing for seamless integration to enhance efficiency and sustainability.

What measurable benefits can a company expect after adopting automated packing machines?

Companies can expect measurable benefits such as reduced packaging waste, lower energy consumption, enhanced supply chain efficiency, cost savings from reduced material usage, improved inventory management, and potentially improved brand reputation due to eco-friendly practices.

How do automated packing machines contribute to reducing carbon footprint in manufacturing?

Automated packing machines contribute to reducing the carbon footprint by optimizing packaging sizes, reducing material waste, and enhancing transportation efficiency. These machines enable companies to use resources more efficiently, leading to decreased emissions associated with production, transportation, and waste management.

Conclusion

In conclusion, the incorporation of automatic industrial packing production machines in manufacturing operations presents a significant opportunity to embrace sustainability. Through their eco-friendly features, reduction of material waste, and positive impact on the supply chain, these machines not only optimize processes but also contribute to a greener and more efficient industrial landscape. The journey towards sustainability in manufacturing is ongoing, and the integration of innovative technologies like automated packing machines paves the way for a brighter, more environmentally conscious future.