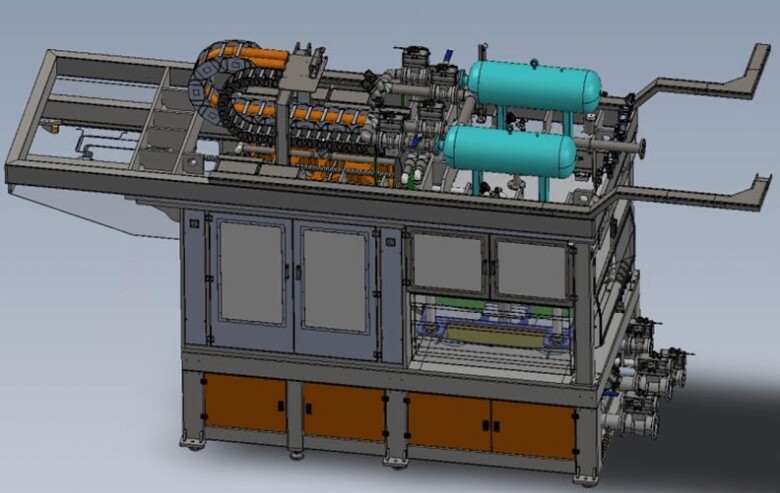

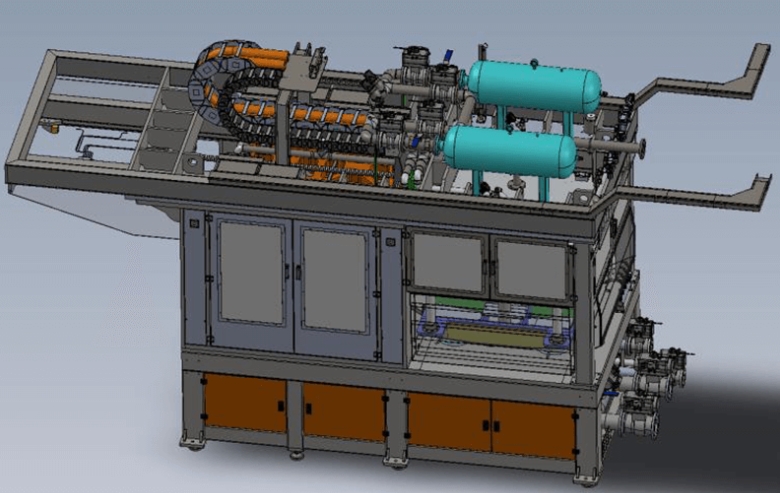

In today's competitive industrial landscape, efficiency stands as a cornerstone for success. Among the technological advancements changing manufacturing processes, automatic industrial packing machines have emerged as a game-changer. These automated systems streamline packing operations, offering multifaceted benefits that significantly elevate productivity, precision, and overall operational efficiency.

Streamlined Operations

Automatic industrial packing machines bring a systematic approach to the packaging process. They seamlessly integrate with production lines, allowing for a continuous and uninterrupted workflow.

Automatic industrial packing production machines perform tasks such as weighing, sorting, filling, sealing, and labeling with high precision and speed, minimizing human error and ensuring consistency in packaging quality.

By automating repetitive tasks, these machines optimize resource utilization, allowing human labor to focus on more complex or strategic aspects of production.

Increased Speed and Productivity

Speed is a crucial factor in modern manufacturing. Automatic packing machines operate at accelerated rates compared to manual labor, enhancing the overall output of packaged goods.

The swift and continuous operation of these automatic industrial packing production machines ensures a rapid turnaround time, meeting the demands of high-volume production without compromising quality.

This increased speed translates directly into higher productivity, enabling companies to meet market demands efficiently and potentially explore new market opportunities.

Improved Accuracy and Consistency

Precision is a hallmark of automated systems. These packing machines execute tasks with consistent accuracy, ensuring uniformity in packaging sizes, weights, and quality.

Advanced sensors and control mechanisms incorporated into industrial packaging production equipment guarantee precise measurements, reducing product wastage and enhancing customer satisfaction by delivering consistently packaged products.

Cost-efficiency and Resource Optimization

While the initial investment in automatic packing machines may seem substantial, the long-term benefits outweigh the costs. These machines operate efficiently, minimizing resource wastage and reducing overhead expenses.

By streamlining operations and optimizing resource utilization, these machines lower labor costs, decrease packaging material wastage and minimize errors, ultimately contributing to improved profitability.

Adaptability and Customization

Modern automatic packing machines offer a high degree of flexibility and adaptability. They can be programmed and adjusted to accommodate various packaging formats, sizes, and materials.

This flexibility enables manufacturers to swiftly adapt to changing market trends, consumer preferences, and regulatory requirements without significant downtime or retooling expenses.

Enhanced Safety and Compliance

Automated packing machines adhere to stringent safety standards, reducing the risk of workplace accidents associated with manual packaging processes.

Compliance with industry regulations and standards is paramount. These machines are designed to meet regulatory requirements, ensuring that packaged goods meet quality and safety standards before reaching consumers.

Data-Driven Insights and Monitoring

Many automatic packing machines are equipped with data collection and analysis capabilities. They generate valuable insights into production metrics, such as throughput, downtime, and efficiency.

Real-time monitoring allows for proactive maintenance, minimizing potential breakdowns and optimizing machine performance, thereby maximizing overall efficiency.

Conclusion

The integration of automatic industrial packing machines represents a shift in manufacturing operations. These advanced industrial packaging production equipment bring forth a multitude of benefits, from increased speed and accuracy to cost-efficiency and adaptability.

By changing the packaging process, these machines empower industries to meet the demands of a dynamic market landscape while ensuring consistency, quality, and optimal resource utilization. As technology continues to evolve, the role of these automated systems will undoubtedly expand, further enhancing the efficiency and competitiveness of industrial sectors worldwide.