In the ever-evolving landscape of manufacturing and production, the choice of an automatic packing machine holds pivotal importance. These industrial packaging production equipment streamline the packaging process, enhancing efficiency and ensuring product quality. However, selecting the right automatic packing machine demands careful consideration of various factors to align with specific business needs and optimize operations.

Understanding Your Packaging Needs

● Begin by comprehensively evaluating your packaging requirements. Consider the type and volume of products to be packaged, packaging materials, desired output, and packaging formats (e.g., bags, pouches, boxes).

● Assess if the automatic industrial packing production machine should handle multiple product sizes and types or cater to a specialized product range.

Type of Automatic Packing Machines

● Familiarize yourself with the types of automatic packing machines available, such as vertical form-fill-seal (VFFS), horizontal form-fill-seal (HFFS), cartooning machines, case packing machines, and more.

● Each type serves distinct purposes and suits specific packaging needs. For instance, VFFS machines are ideal for packaging powders, liquids, and granular products, while HFFS machines are suitable for solid items.

Packaging Speed and Capacity

● Determine the desired production speed and output capacity of the automatic industrial packing production machine. Consider both current needs and future growth projections to ensure the machine's longevity and adaptability.

● High-speed machines may be suitable for large-scale production, while moderate-speed machines could suffice for smaller operations without compromising efficiency.

Technology and Features

● Look for advanced technological features that align with your production goals. Features like automatic cleaning systems, remote monitoring, and integration capabilities with other production line machinery can enhance efficiency and reduce downtime.

● Opt for machines equipped with user-friendly interfaces and customizable settings to accommodate diverse packaging requirements.

Quality and Reliability

● Prioritize the quality and reliability of the machine. Investigate the manufacturer's reputation, product reviews, and warranty terms to ensure long-term reliability and minimal maintenance issues.

● Consider investing in machines from reputable manufacturers known for their durable and dependable equipment.

Space and Installation Requirements

● Evaluate the available space for the installation and operation of the automatic packing machine. Consider the machine's footprint, layout flexibility, and compatibility with your existing production line.

● Ensure that the installation and setup requirements align with your facility's infrastructure to facilitate seamless integration.

Cost Analysis and Return on Investment (ROI)

● Conduct a comprehensive cost-benefit analysis to determine the overall expenses, including initial investment, maintenance, and operational costs, against the expected ROI.

● While price is a crucial factor, prioritize the long-term value and efficiency gains the machine offers rather than solely focusing on upfront costs.

Regulatory Compliance and Standards

● Ensure that the chosen automatic packing machine complies with industry-specific regulations, safety standards, and packaging guidelines. Non-compliance can lead to legal repercussions and compromised product quality.

● Verify certifications and adherence to international quality standards to guarantee the machine meets the requirements.

Training and Support

● Inquire about the training and technical support provided by the manufacturer or supplier. Adequate training for operators ensures optimal machine performance and minimizes errors.

● Consider suppliers that offer responsive customer support and readily available spare parts to address maintenance and repair needs promptly.

Seek Recommendations and Consult Experts

Gather insights and recommendations from industry peers, attend trade shows, and consult with experts in the field. Their experiences and advice can offer valuable perspectives and help in making an informed decision.

In a word, choosing the right automatic industrial packing production machine necessitates a thorough assessment of various factors ranging from production requirements to technological capabilities and cost considerations. By conducting a comprehensive analysis and aligning these considerations with specific business needs, companies can make a prudent investment that enhances productivity, efficiency, and overall packaging quality.

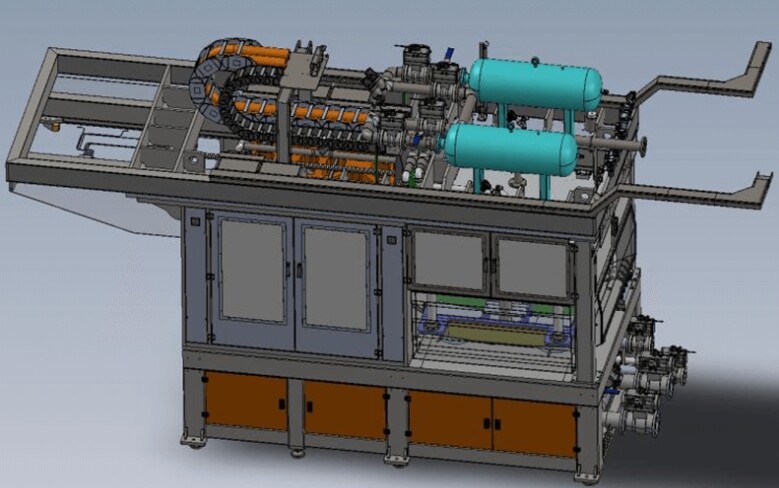

Meishi is committed to providing industrial packaging production equipment of the highest quality. Packaging production equipment helps to streamline your packaging process with clear and simple maintenance processes and a small footprint, making it ideal for your production line. In addition to industrial packaging production equipment, we also supply pulp molding production lines, pulp molding machine processing, and more. Feel free to contact us for more product details.