In the industry of industrial packaging, the diversity in products, sizes, shapes, and materials demands adaptable solutions that traditional standardized packaging equipment often fails to meet

As technology continues to advance, the future of customizable packaging equipment looks promising. Innovations in robotics, automation, and data analytics will further refine the adaptability and flexibility of these machines, making them even more efficient and versatile.

Enter the era of customization and flexibility in industrial packaging production equipment - a shift that caters to the unique needs of various products across industries.

The Demand for Customization: In today's market, consumer preferences are ever-evolving, leading to an array of product variations. From food and beverages to pharmaceuticals and electronics, the need for specialized packaging equipment that can swiftly adapt to these changes is more crucial than ever before.

Challenges of Standardization: Standardized packaging equipment, while efficient for specific products, struggle to accommodate diverse items. Traditional machines built for uniform packaging struggle when faced with irregular shapes, varying sizes, or fragile materials.

Tailoring Solutions for Diverse Products: Customizable packaging machinery has emerged as the solution to these challenges. Manufacturers now offer adaptable equipment that can be modified to suit the precise requirements of different products. This includes adjustable filling mechanisms, variable speed controls, and adaptable packaging materials.

Modularity and Versatility: The key to adapting industrial packaging equipment lies in its modularity. Machines designed with interchangeable parts and modules allow for quick reconfiguration to handle different packaging needs. Versatile systems can accommodate changes in packaging sizes or materials without requiring a complete overhaul.

Advanced Technology Integration: The integration of cutting-edge technology like artificial intelligence and machine learning has revolutionized packaging equipment. Smart machinery can self-adjust, detect variations in products, and optimize packaging processes in real time, enhancing efficiency and flexibility.

Material Diversity and Handling: Customization in packaging equipment extends beyond size and shape variability. It addresses the challenge of diverse packaging materials, enabling machines to handle anything from glass and plastic to cardboard and biodegradable materials effectively.

Efficiency and Cost Savings: While customization may seem costlier initially, the adaptability of these machines leads to long-term savings. By eliminating the need for multiple machines for different products, companies reduce equipment costs and operational downtime.

Meeting Regulatory Standards: Different industries face distinct regulatory requirements for packaging. Customizable equipment allows for easier adherence to these standards by adapting the packaging process to meet specific compliance needs.

Enhanced Productivity and Market Agility: The ability to swiftly switch between different packaging styles or adapt to new product lines enhances a company's agility in responding to market demands. This adaptability translates into improved productivity and a competitive edge.

Collaborative Approach with Manufacturers: To fully harness the benefits of customization, collaboration between manufacturers and packaging equipment suppliers is imperative. Understanding the unique needs of the products and industries helps in crafting tailored solutions.

Explore the Industrial Packaging Production Equipment of Meishi

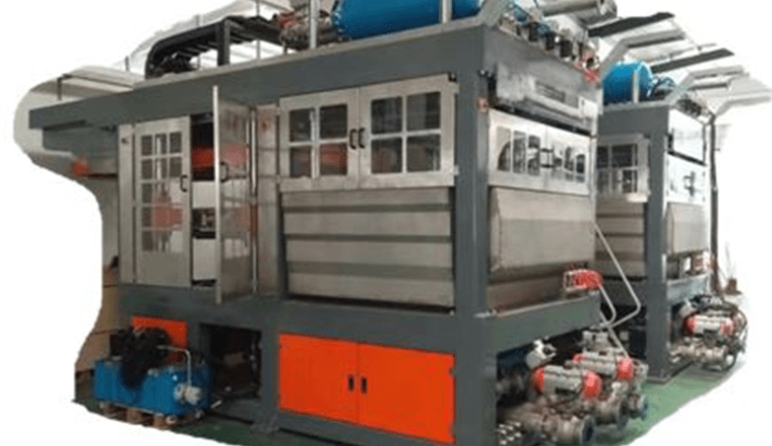

Two Grid Machine- one forming station, one hot pressing station

Industrial packaging production equipment helps to streamline your packaging process with clear and simple maintenance processes and a small footprint, making it ideal for your production line.

● Fully enclosed safety protection.

● European and American design standards, the machine will automatically stop when the door is opened during operation.

● High productivity, high automation, low energy consumption, low labor cost.

● The direct production cost of the product is greatly reduced, which is about 30% lower than the conventional equipment.

● Small occupied area

● Fully automatic PLC control screen and easy to operate.

● Maintenance process clear and simple

| Model | Two Grid Machine |

| Mould size: 1400x1300mm | |

| Template size | 1400x1300mm |

| Machine structure | One forming station, |

| One hot pressing station | |

| Forming method | Reciprocating |

| Heating method | Thermal oil or electrical |

| Drying method | Drying in mould |

| Hot pressing pressure | 0-35 tongs |

| Product height range | <100mm |

| Transfer method | Upper mold moves |

| Pressure | Hydraulic |

| Daily capacity | Base on products |

Applications

● high-end electronic product packaging

● cosmetics products packaging

● high-end liquor packaging

● high added value art

● crafts packaging, etc

Customization and flexibility in industrial packaging equipment represent a pivotal shift in addressing the challenges posed by the diversity of products in today's markets. The ability to tailor packaging solutions to fit varying product specifications not only enhances efficiency but also ensures compliance, cost-effectiveness, and agility in meeting consumer demands. Contact Meishi today and find the perfect solution for your project.