Industrial packaging plays a crucial role in safeguarding products during storage, transportation, and handling. The efficiency and quality of packaging significantly impact a company's supply chain and customer satisfaction. In the realm of industrial packaging production, hot press machines stand out as essential equipment that changes the process by offering enhanced precision and productivity.

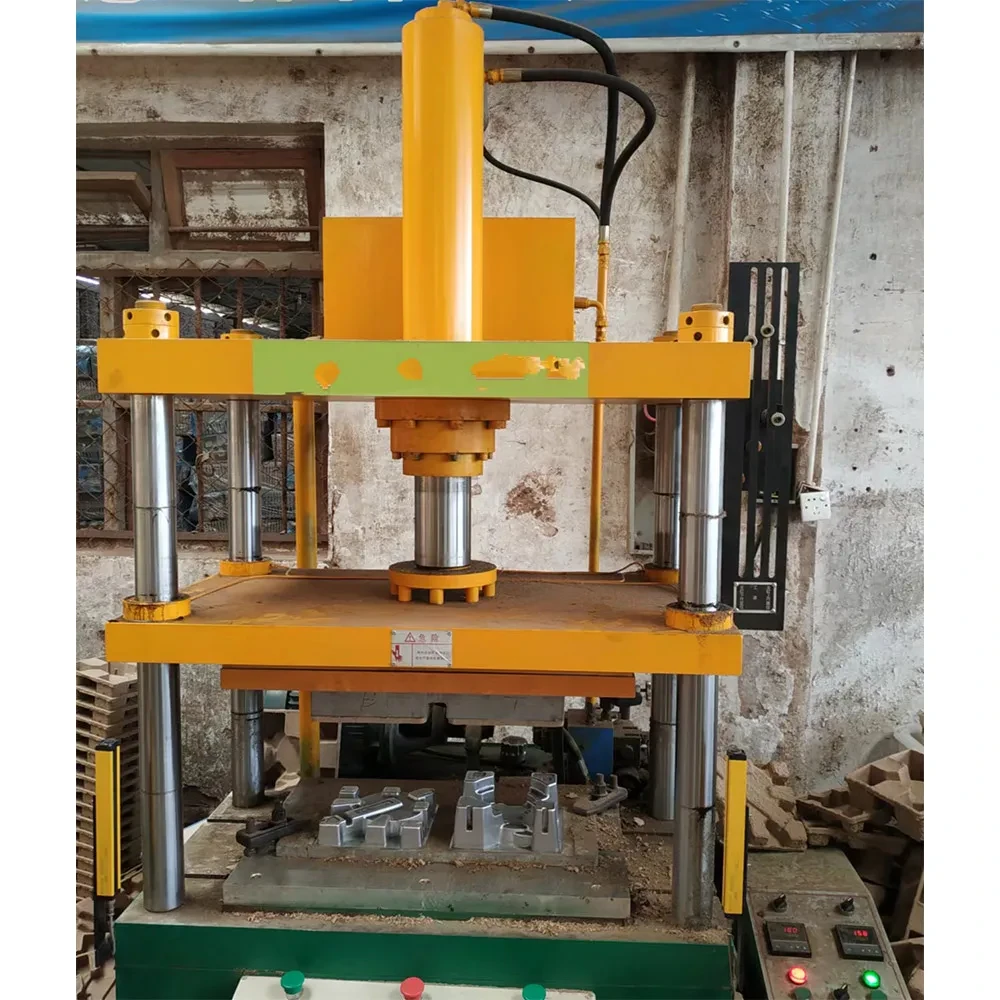

Hot Press Machines

Hot press machines are pivotal in the manufacturing of industrial packaging materials. These machines utilize heat and pressure to bond layers of materials together, creating robust and durable packaging components.

The process involves placing the materials to be bonded between heated platens within the machine. The application of controlled heat and pressure activates the adhesive properties within the materials, fusing them to form a unified and sturdy composite.

Benefits of Hot Press Machines in Industrial Packaging Production:

Precision and Consistency: These machines offer precise control over temperature and pressure settings, ensuring consistent and uniform bonding across the entire surface. The precision achieved significantly reduces material wastage and enhances the overall quality of the packaging materials produced.

Versatility: Hot press machines cater to a wide range of materials and can be adapted to accommodate various sizes and thicknesses. They enable the production of diverse packaging solutions, from thin and flexible materials to thicker and more robust options, meeting specific industry requirements.

Efficiency and Productivity: The automation and advanced features integrated into modern hot press machines streamline the production process. High-speed operations and optimized cycle times contribute to increased output, allowing manufacturers to meet demanding production schedules effectively.

Improved Material Properties: The bonding process facilitated by hot press machines enhances the structural integrity and durability of packaging materials. It results in products that exhibit superior strength, resistance to moisture, and overall longevity, ensuring the protection of packaged goods throughout the supply chain.

Applications Across Industries:

Hot press machines find extensive applications in producing dry pulp molded products that serve diverse purposes across multiple industries. These machines play a pivotal role in crafting essential items like egg cartons, cup holders, and shoe inserts, catering to the packaging needs of the food, beverage, and footwear industries, respectively.

Additionally, hot press machines contribute significantly to the manufacturing of various industrial packages, ensuring the secure and reliable transportation of goods across sectors such as manufacturing, electronics, and automotive. Their adaptability to work with different materials allows for the creation of intricately designed and precisely formed packaging solutions, fulfilling specific industry requirements with ease.

The versatility of hot press machines in producing dry pulp molded products underscores their significance in delivering cost-effective and eco-friendly packaging solutions for a wide array of products, ranging from fragile goods to heavy-duty industrial components.

Conclusion

Hot press machines stand as indispensable equipment in the realm of industrial packaging production, playing a pivotal role in ensuring the quality, efficiency, and versatility of packaging materials. With ongoing technological innovations, these machines continue to evolve, promising further enhancements in production processes and sustainability, ultimately contributing to the seamless and reliable delivery of goods across various industries.