Industrial packaging plays a pivotal role in protecting goods during transportation, ensuring product integrity and safety. One of the industrial packaging production equipment is a servo-forming machine.

Servo Forming Machines

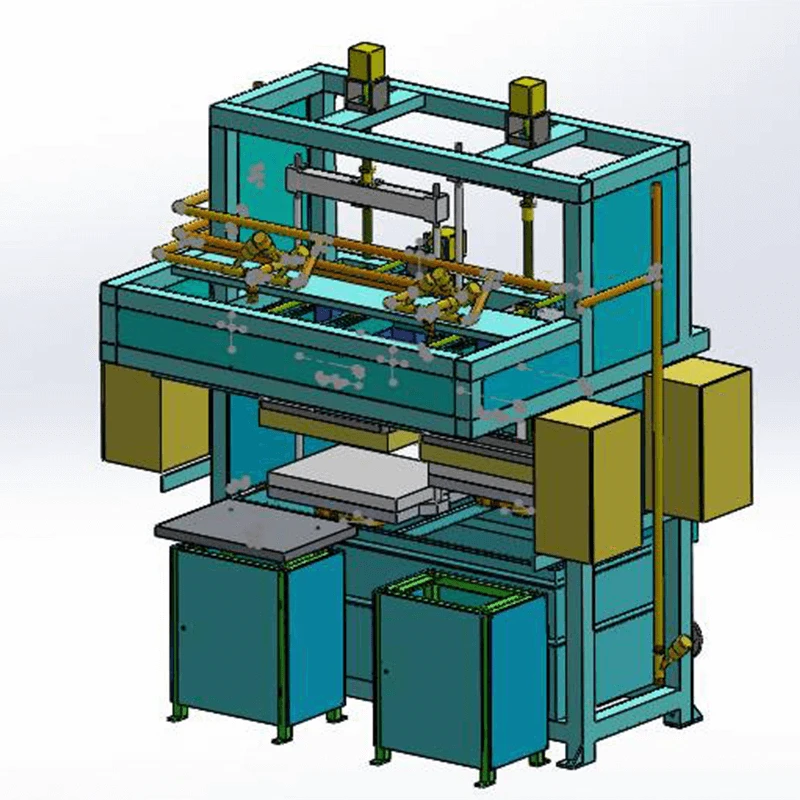

Servo-forming machines are sophisticated equipment used in the production of industrial packaging. These machines utilize servo motors for precise control over the forming process, enabling high accuracy and consistency in packaging production. They are designed to handle various materials such as plastics and cardboard to create diverse packaging solutions for different industries.

Why Use Servo Forming Machines?

The evolution of packaging production equipment has seen significant advancements, with servo-forming machines emerging as a cornerstone technology in modern manufacturing processes.

Enhanced Efficiency and Precision: One of the primary advantages of servo-forming machines is their ability to offer unparalleled precision in the production process. The servo-driven technology allows for precise control of movements, resulting in accurate cuts, shapes, and sizes of packaging materials. This precision contributes to minimizing material waste, optimizing production efficiency, and ensuring uniformity in packaging quality.

Flexibility in Design and Customization: Servo-forming machines provide manufacturers with increased flexibility in designing packaging solutions. They can adapt to produce various shapes, sizes, and configurations, catering to specific product requirements. The ability to customize packaging designs swiftly meets the demands of diverse industries, including food, pharmaceuticals, electronics, and more.

Speed and Productivity: With their high-speed capabilities and efficient servo-driven mechanisms, these machines significantly enhance production rates. They can handle rapid forming and cutting processes, increasing the overall output without compromising quality. Improved production speeds contribute to meeting market demands promptly, enabling manufacturers to respond quickly to fluctuations in consumer needs.

Quality Assurance and Consistency: Servo-forming machines excel in maintaining consistent quality throughout the packaging production process. Precise control over every step ensures uniformity in the manufactured packaging, reducing defects and enhancing overall product integrity. Quality assurance is crucial, especially in industries where packaging directly impacts product safety and shelf life.

Integration of Advanced Technologies: Many modern servo-forming machines incorporate advanced technologies such as automation, robotics, and AI-driven systems. Integration with automation streamlines production lines, reducing human error and increasing operational efficiency. AI-driven systems enable predictive maintenance, minimizing downtime and optimizing machine performance, ensuring continuous and reliable operation.

Environmental Sustainability: These machines contribute to sustainable packaging practices by minimizing material wastage. Precise cutting and shaping techniques optimize material usage, reducing environmental impact by decreasing the volume of discarded materials. Furthermore, the ability to work with recyclable materials aligns with the growing emphasis on eco-friendly packaging solutions.

Future Prospects and Industry Trends: The packaging industry continues to evolve, with a focus on sustainable practices, automation, and customization. Servo-forming machines are expected to undergo further advancements, integrating more sophisticated technologies to meet evolving market demands. Embracing digitization, IoT connectivity, and predictive analytics will likely define the future landscape of industrial packaging production.

Applications of Servo Forming Machine

Recyclable Industrial Packaging: Tailored for a wide array of industrial items such as TV components, cookers, batteries, air conditioner parts, and various electrical appliances. The machine's ability to accommodate diverse shapes and sizes ensures it can create custom packaging that provides optimal protection during transportation.

Versatile Tray and Carrier Production: Specialized in producing various types of trays and carriers including egg trays, egg boxes, fruit trays, 2-cup and 4-cup carriers, as well as seeding cups. Its flexibility in mold changes enables swift transitions between different products, catering to the needs of industries ranging from agriculture to food and beverage packaging.

Disposable Medical Care Products: Ideal for the production of disposable medical care products such as bedpans, sick pads, urinal pans, and other items crucial for healthcare facilities. The machine's precision and ability to work with different materials meet the stringent quality and hygiene standards required for medical applications.

The versatility of the Servo Forming Machine extends across multiple industries, enabling the production of a wide range of packaging solutions. Its adaptability to diverse materials, precise forming capabilities, and ability to cater to specific product dimensions make it a valuable asset for manufacturers across various sectors, ensuring the creation of customized, high-quality, and environmentally conscious packaging solutions.

Conclusion

Servo-forming machines represent a significant leap in the evolution of industrial packaging production equipment. Their precision, speed, flexibility, and integration of advanced technologies have revolutionized the manufacturing process. As industries prioritize efficiency, customization, and sustainability, these machines are poised to play an increasingly pivotal role in shaping the future of packaging production.

Meishi is one of the Chinese industrial packaging production equipment manufacturers. When it comes to industrial packaging production equipment, we have a variety of options to suit your needs. You are welcome to call us for consultation and cooperation at any time, and we will provide you with high-quality custom industrial packaging production equipment at reasonable prices.