An Automatic Industrial Packing Production Machine refers to a sophisticated piece of equipment designed to automate the packaging process in industrial settings. These machines are engineered to handle various tasks involved in packaging products efficiently, accurately, and at high speeds.

Automatic industrial packing production machines change the packaging process by automating repetitive tasks, minimizing human intervention, and ensuring that products are efficiently and accurately packaged for distribution and sale.

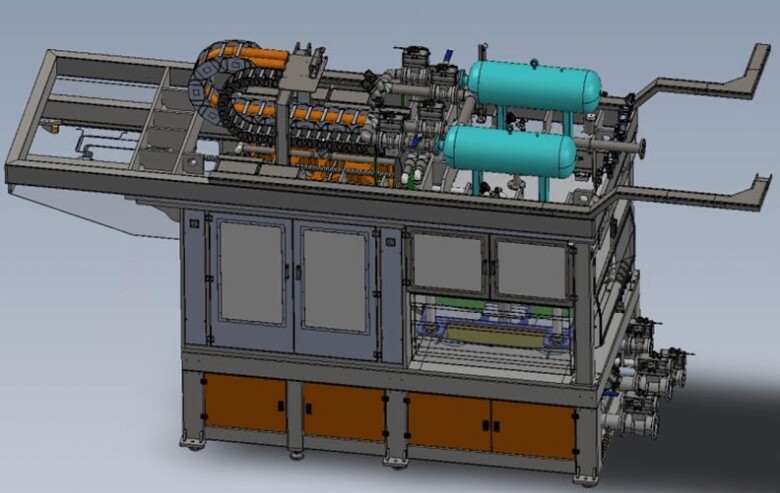

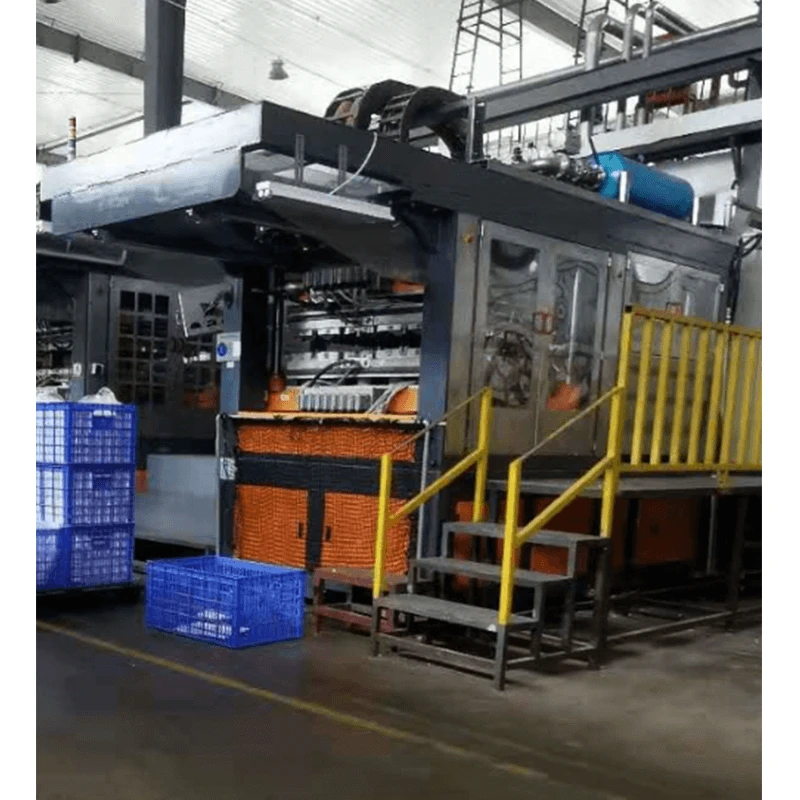

Features of Meishi Automatic Industrial Packing Production Machine

● High precision, high stability.

● Forming and hot pressing two–in–one design.

● position, pressure, and temperature can be adjusted accurately.

● Fully enclosed safety protection.

● European and American design standards, the machine will automatically stop when the door is opened during operation.

● High productivity, high automation, low energy consumption, low labor cost.

● The direct production cost of the product is greatly reduced, which is about 30% lower than the conventional equipment.

● Small occupied area

● Fully automatic PLC control screen and easy to operate.

● Maintenance process clear and simple

| Model | Two Grid Machine |

| Mould size: 1400x1300mm | |

| Template size | 1400x1300mm |

| Machine structure | One forming station, |

| One hot pressing station | |

| Forming method | Reciprocating |

| Heating method | Thermal oil or electrical |

| Drying method | Drying in mould |

| Hot pressing pressure | 0-35 tongs |

| Product height range | <100mm |

| Transfer method | Upper mold moves |

| Pressure | Hydraulic |

| Daily capacity | Base on products |

Application of Automatic Industrial Packing Production Machine

Automatic industrial packing production machines play a pivotal role in various industries, providing efficiency, precision, and consistency in packaging different types of products.

High-end Electronic Product Packaging: Delicate electronic devices require precise packaging to ensure their safety during transport. Automated packing machines can handle tasks like bubble wrapping, cushioning, and sealing electronic products in custom-fit boxes or containers. These machines ensure a snug fit while safeguarding the products from shocks or vibrations.

Cosmetics Products Packaging: Cosmetics often demand sophisticated packaging to maintain product integrity and aesthetics. Automated machines excel in tasks like filling containers, capping, labeling, and shrink-wrapping. These machines maintain hygiene standards, enhance production speed, and provide consistent packaging quality, crucial in the cosmetics industry.

High-end Liquor Packaging: The packaging of high-end liquors involves precision in bottle handling, labeling, and sealing, and often requires customization for branding purposes. Automatic packing machines efficiently manage these tasks, ensuring uniformity in presentation and protecting the bottles from breakage or damage during transit.

High-Added Value Art: Packaging high-value art pieces demand special care to prevent any damage during handling or shipping. Automated machines offer custom solutions for securing fragile items, using techniques like foam or cushioning insertion, custom crate creation, and precise wrapping to ensure the art's safety.

Crafts Packaging, etc.: Crafts packaging may involve varying shapes and sizes, which can be challenging for manual packing processes. Automatic packing machines adapt to different dimensions, efficiently managing diverse packaging needs. They handle tasks like filling, sealing, and labeling, ensuring consistency and speed in packaging crafts.

In all these applications, automatic industrial packing production machines offer several advantages:

Speed and Efficiency: These machines significantly speed up the packaging process, increasing overall production efficiency.

Consistency: They ensure uniformity and precision in packaging, reducing errors and inconsistencies often seen in manual packing.

Customization: These machines can be programmed to accommodate various product sizes, shapes, and packaging requirements, providing tailored solutions for each product category.

Reduced Labor Costs: By automating packaging processes, businesses can cut down on labor expenses and allocate human resources to other critical tasks.

Improved Safety and Protection: Automated packaging ensures products are properly secured and protected, reducing the risk of damage during transportation.

Overall, automatic industrial packing production machines play a crucial role in enhancing productivity, maintaining product quality, and meeting the specific packaging needs of various products across different industries.

Meishi is your trusted partner when planning to invest in automatic industrial packing production machines, and we are committed to providing information about our products to help you make informed decisions.