Industrial packaging production equipment is highly automated, consumes less energy, has lower labor costs, reduces the use of packaging materials, and increases packaging speed.

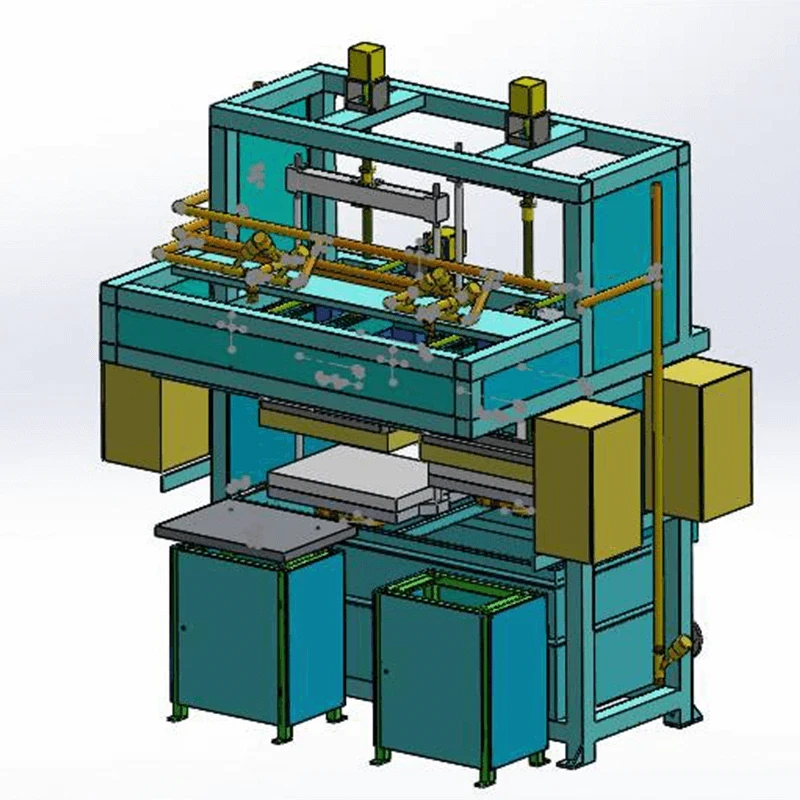

Invest in Meishi Servo Forming Machine

Meishi servo forming machine helps streamline your packaging process, with clear and simple maintenance processes and a small footprint, making it ideal for your production line.

Servo Control and Durability: The machine's servo control technology ensures precise and reliable operation, offering high durability due to its advanced engineering. This feature guarantees consistent performance over extended periods, minimizing downtime and maintenance costs.

User-Friendly Operation and Maintenance: Its user interface is designed for ease of use, ensuring operators can efficiently control and monitor the machine's functions. Clear and straightforward maintenance procedures make it convenient for operators to perform routine upkeep, reducing the risk of unexpected breakdowns and ensuring consistent productivity.

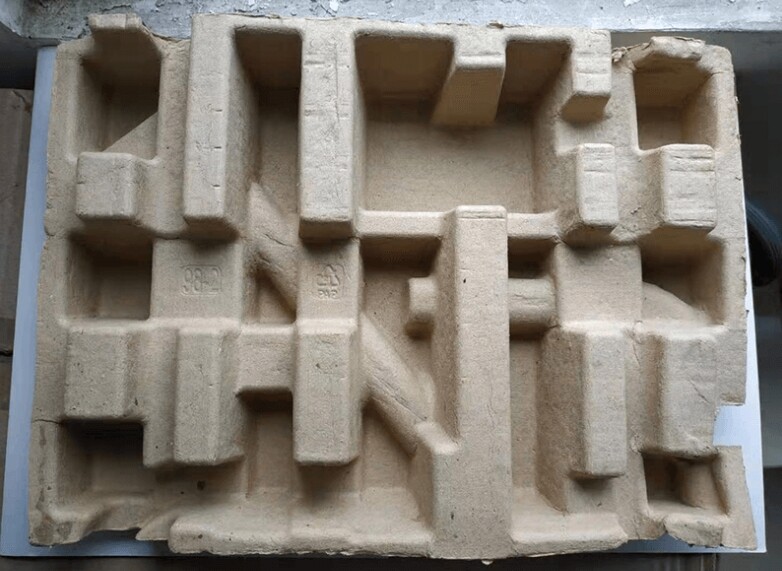

Specialized for Recyclable Pulp Molding: Specifically tailored for recyclable pulp molding, the machine excels in creating industrial package items with a focus on sustainability. Its compatibility with recyclable materials aligns with the growing emphasis on eco-friendly packaging solutions, meeting industry standards and consumer demands for sustainability.

Automated Product Collection: After the production process, the machine facilitates the automatic dropping of finished products onto the collection table, streamlining workflow efficiency. This feature reduces manual handling, minimizing the risk of damage to the products and ensuring a smoother production flow.

Dual Working Stations for Product Variation: Equipped with two working stations, the machine enables simultaneous production of two different types of products. Through the simple process of mold changes, it can swiftly transition to manufacturing various types of products, enhancing its versatility and meeting diverse market demands.

Corrosion-Resistant Pulp Tank: The pulp tank, constructed from SUS304 stainless steel, boasts exceptional corrosion resistance properties. This feature ensures longevity and reliability in the machine's operation, maintaining product quality and preventing material contamination during the production process.

Advanced Control Mechanisms: Utilizing PLC and touchscreen controls, the machine offers precise and intuitive control over its operations. This sophisticated control system enhances efficiency, allowing operators to manage and adjust production parameters with ease, optimizing output quality.

Servo Motor-Driven Mechanisms: The bottom mold's reciprocating drive, powered by a servo motor, ensures precise movements and accurate shaping during the production process. Additionally, the servo motor driving the forward-backward motion of the mold further contributes to the machine's precision and reliability in creating consistent products.

The Servo Forming Machine stands out as a technologically advanced and versatile solution in the realm of industrial packaging production equipment. Its integration of servo control, recyclable material suitability, dual working stations, corrosion-resistant construction, and advanced control mechanisms positions it as a reliable and efficient choice for manufacturers seeking high-quality, customizable, and eco-friendly packaging solutions.

Applications of Servo Forming Machine

Recyclable Industrial Packaging: Tailored for a wide array of industrial items such as TV components, cookers, batteries, air conditioner parts, and various electrical appliances. The machine's ability to accommodate diverse shapes and sizes ensures it can create custom packaging that provides optimal protection during transportation.

Versatile Tray and Carrier Production: Specialized in producing various types of trays and carriers including egg trays, egg boxes, fruit trays, 2-cup and 4-cup carriers, as well as seeding cups. Its flexibility in mold changes enables swift transitions between different products, catering to the needs of industries ranging from agriculture to food and beverage packaging.

Disposable Medical Care Products: Ideal for the production of disposable medical care products such as bedpans, sick pads, urinal pans, and other items crucial for healthcare facilities. The machine's precision and ability to work with different materials meet the stringent quality and hygiene standards required for medical applications.

The versatility of the Servo Forming Machine extends across multiple industries, enabling the production of a wide range of packaging solutions. Its adaptability to diverse materials, precise forming capabilities, and ability to cater to specific product dimensions make it a valuable asset for manufacturers across various sectors, ensuring the creation of customized, high-quality, and environmentally conscious packaging solutions.

MEISHI is committed to providing high-quality industrial packaging production equipment, which includes servo hot pressing machines, servo molded pulp forming machines, the best trimming machine industrial, and more. In addition to industrial packaging production equipment, we also offer automatic tableware production lines, pulp molded production lines, and more. Contact us for more information.