- home

- About Us

-

Products

- Paper lid and cup holder equipment

- Pulp mould Tableware Automatic Production Line- Robot Transfer Product

- High Quality Packaging Production equipment

- Industrial Packaging Production equipment

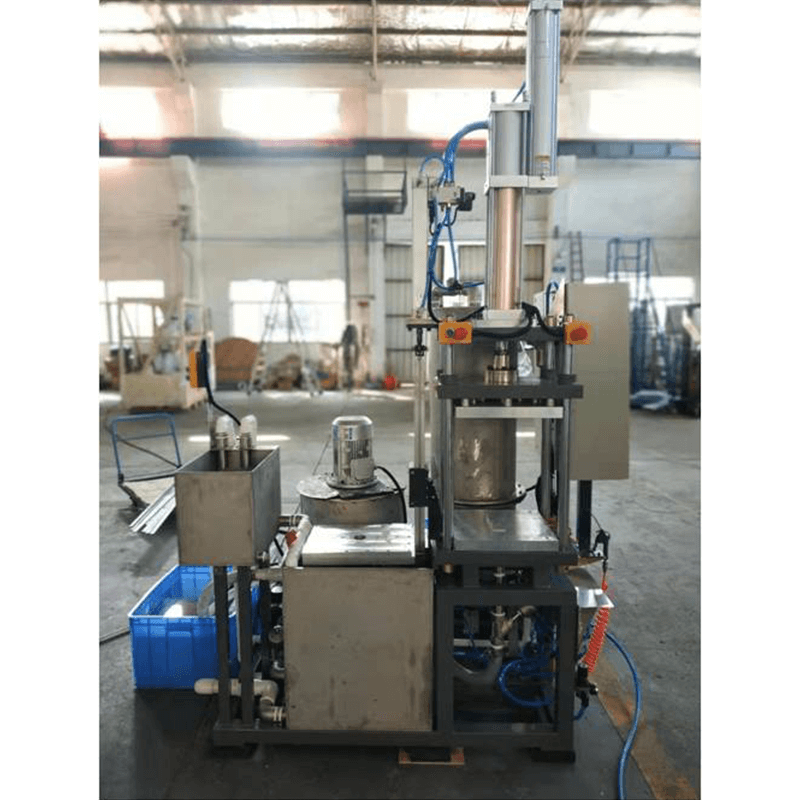

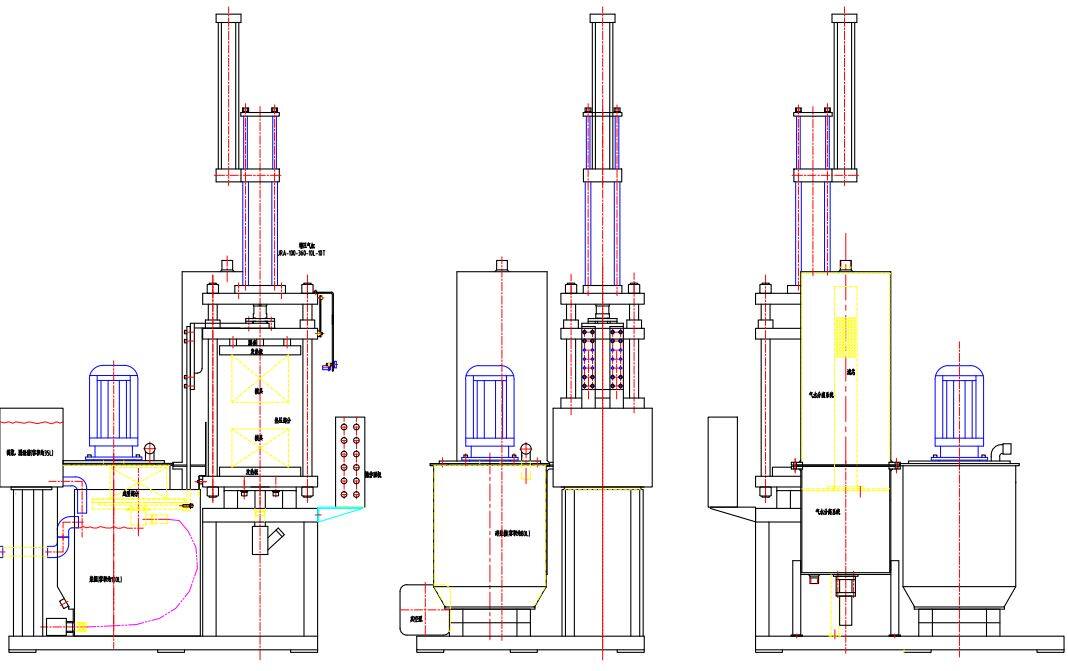

- Small integrated equipment for testing and sample making

- customized, Non-standard design and manufacture

- Pulping System, pulp preparetaion system

- Pulp mould Moulds, Tooling

- Auxiliary system

- Pulp tableware , Pulp containers, Pulp Bowl, Pulp plates

- High Quality Packaging Pulp Tray Electronic product tray, cosmetic tray

- Industrial Packaging Pulp Tray tools packing, accessories packing , household applicances packing

- liquid Filling and packaging line

- News

- Service

- Video

- Contact Us